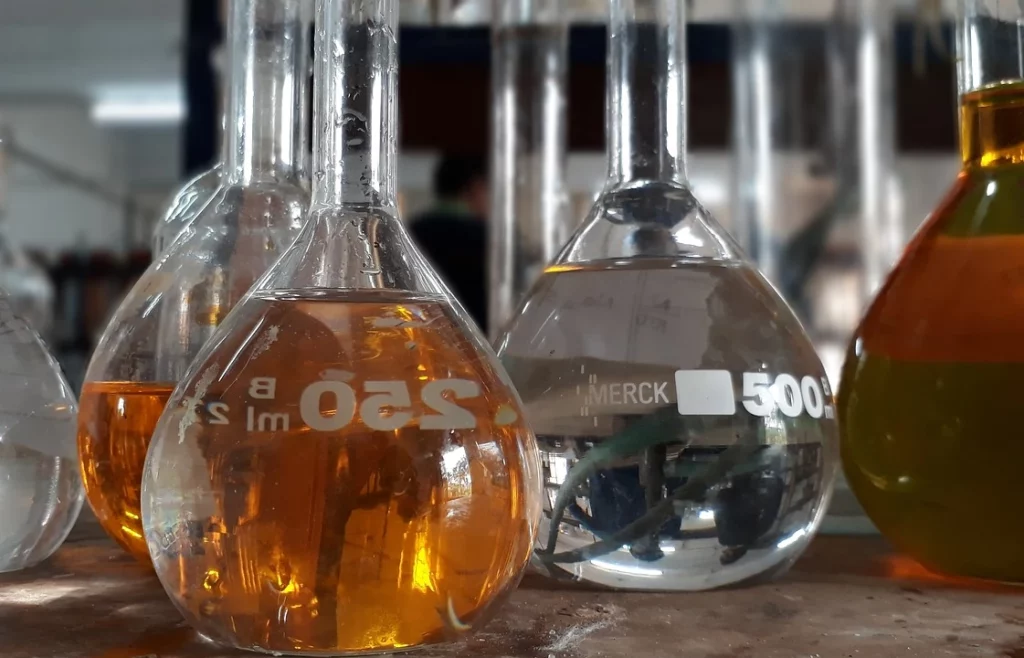

We’ve created a science-backed solution to the global waste plastics problem with our Braven Reactor Train™ (or BRT™) that is turn-key, good for the planet, good for business and available immediately.

Braven Environmental™ Technology Gives Used Plastic New Life.

Plastics aren't going away. Their applicability in everything from medical, to food, to industrial, is something that cannot be replaced, but there needs to be a solution to take care of the volume of plastics that are being created out of necessity.

Mechanical recycling takes care of only 10% of used plastics. At Braven, we have the ability to process nearly 90% of all plastics.

Learn more about how Braven's advanced technology can give a second life to waste plastics today.

Braven Environmental™ Technology Gives Used Plastic New Life.

Plastics aren't going away. Their applicability in everything from medical, to food, to industrial, is something that cannot be replaced… but there needs to be a solution to take care of the volume of plastics that are being created out of necessity.

Mechanical recycling takes care of only 10% of used plastics. At Braven, we have the ability to process nearly 90% of all plastics.

Learn more about how Braven's advanced technology can give a second life to waste plastics today.

Braven News

Braven Environmental™ is expanding rapidly, and making headlines for our waste innovation and economic development efforts nation-wide.